Problems

Problems

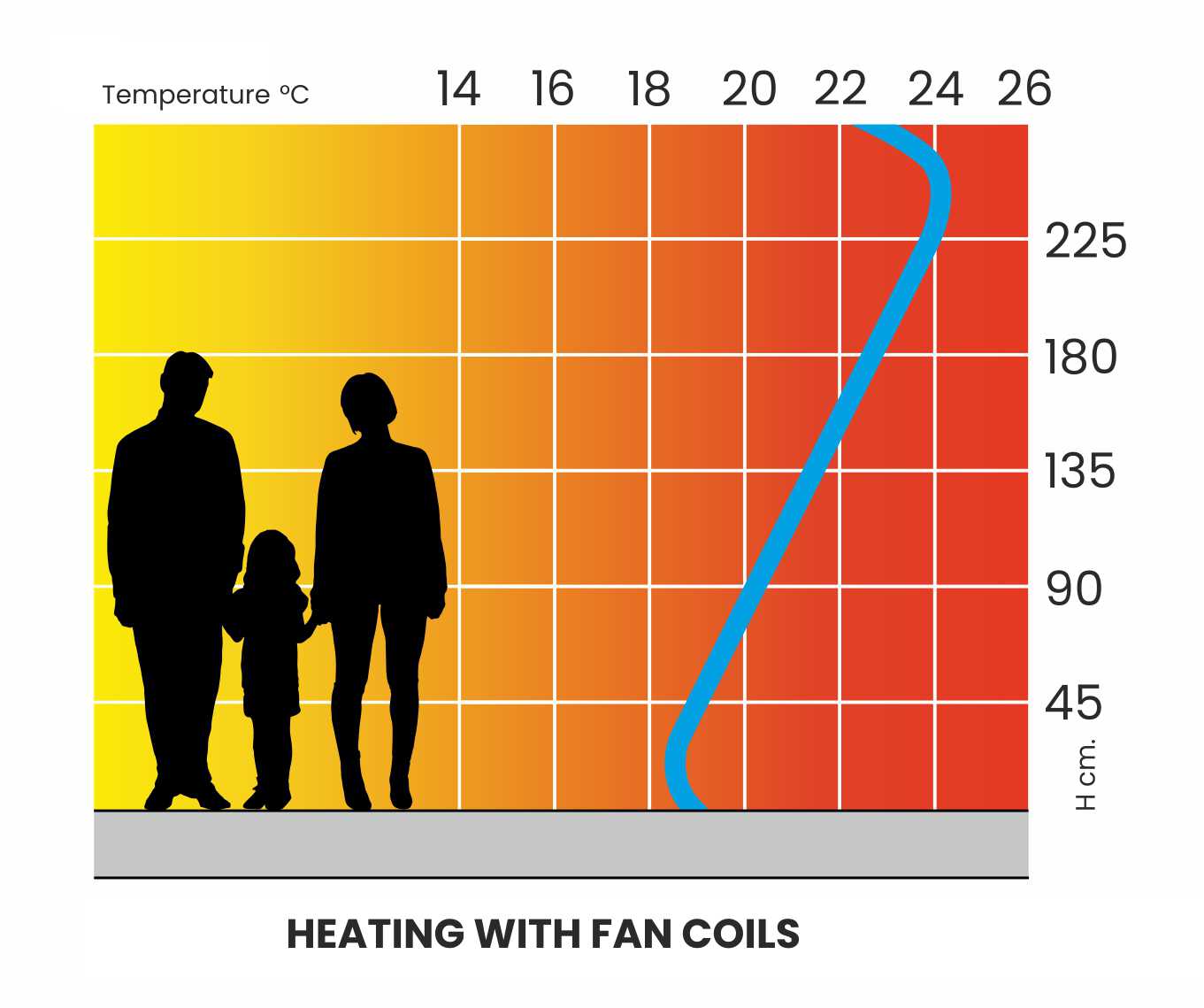

To thermoregulate a room in a uniform, balanced and healthy way is a goal that must absolutely be achieved if you want to talk about well-being. And if we associate well-being with the subjective perception that each individual has when he desires warmth in the winter season and when he desires cool in the summer, we understand how decisive it can be to make well-considered and conscious choices. Choices that, in the case of a heating system, tend to meet 3 technical options: radiators, radiant (floor, wall or ceiling), fan coils.

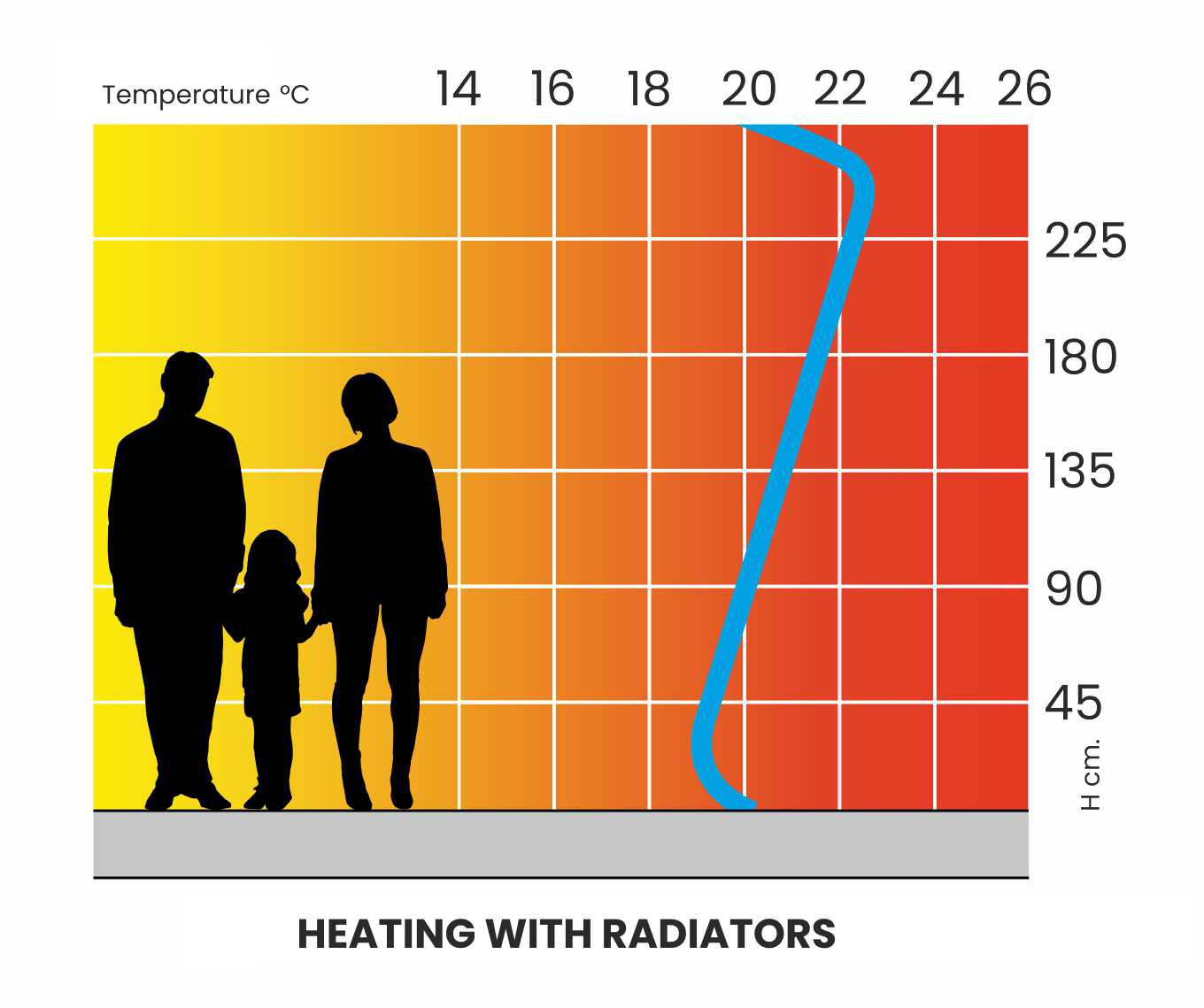

If the perception of well-being is a subjective principle, what are the objective aspects that we can classify among the most negative and to be avoided in heating or cooling a living room? Without going into too much in-depth analysis, we can list the most recognized:

- Excessive energy consumption

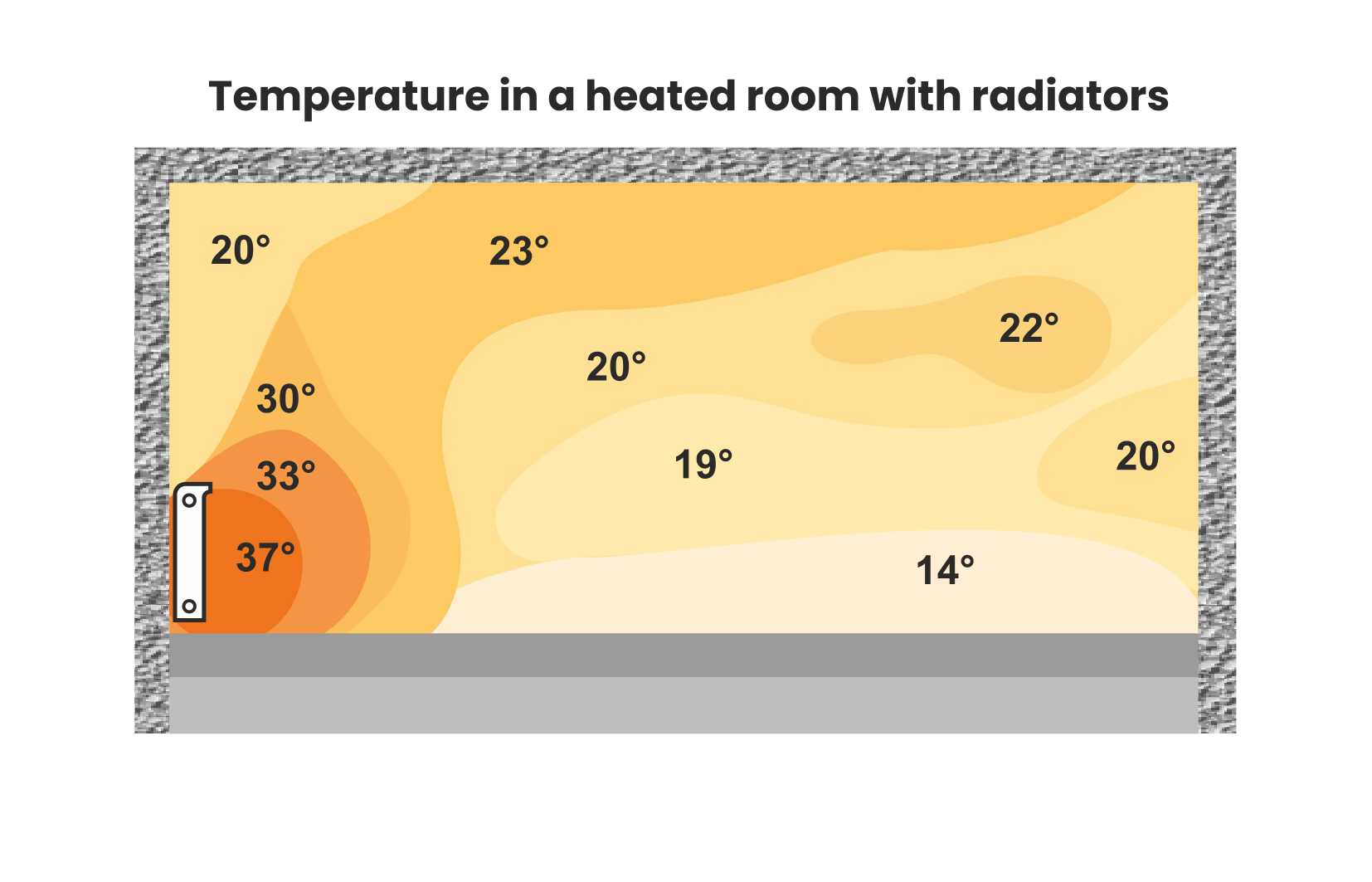

- Convective motions of dust

- Dryness of the respiratory tract

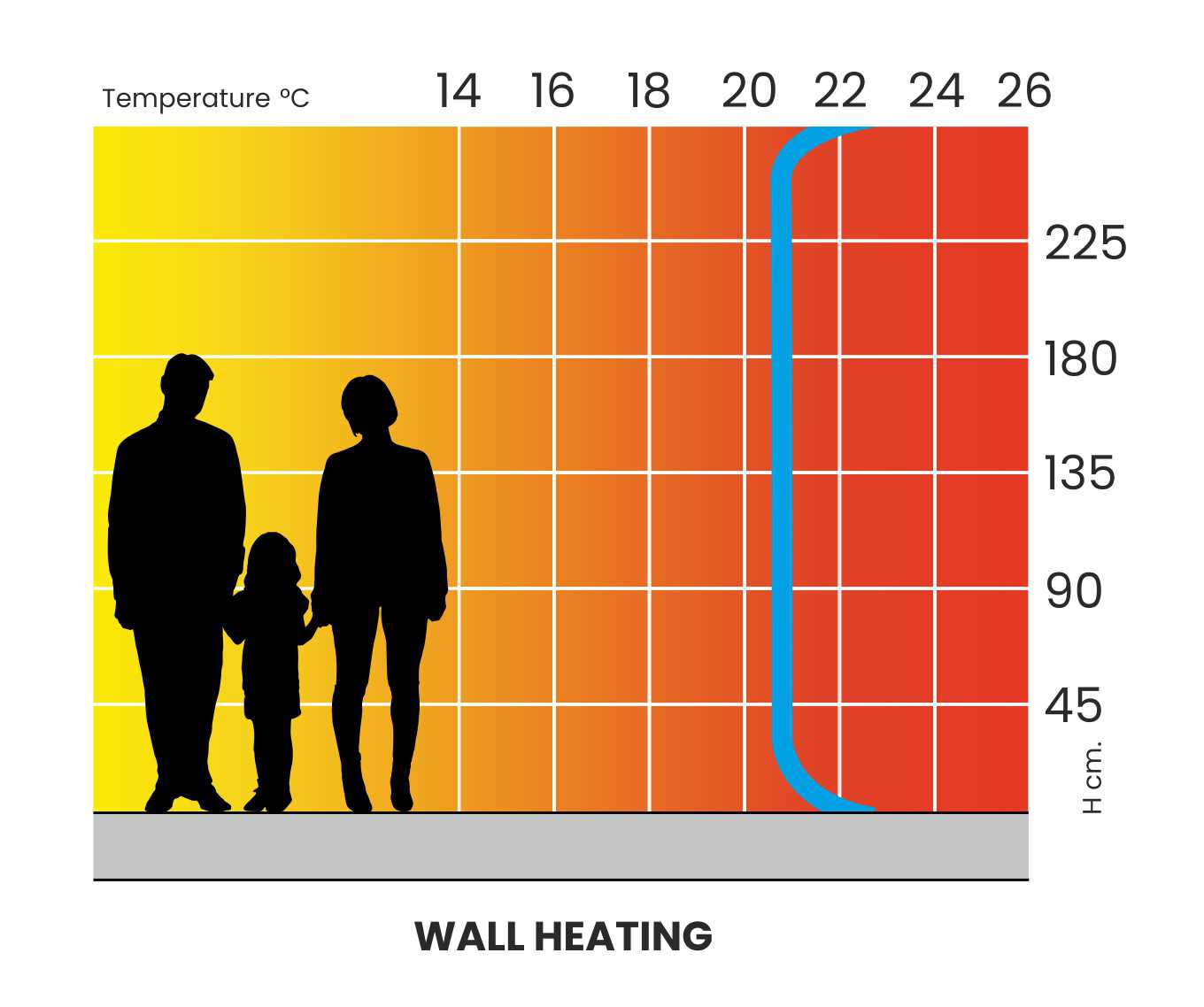

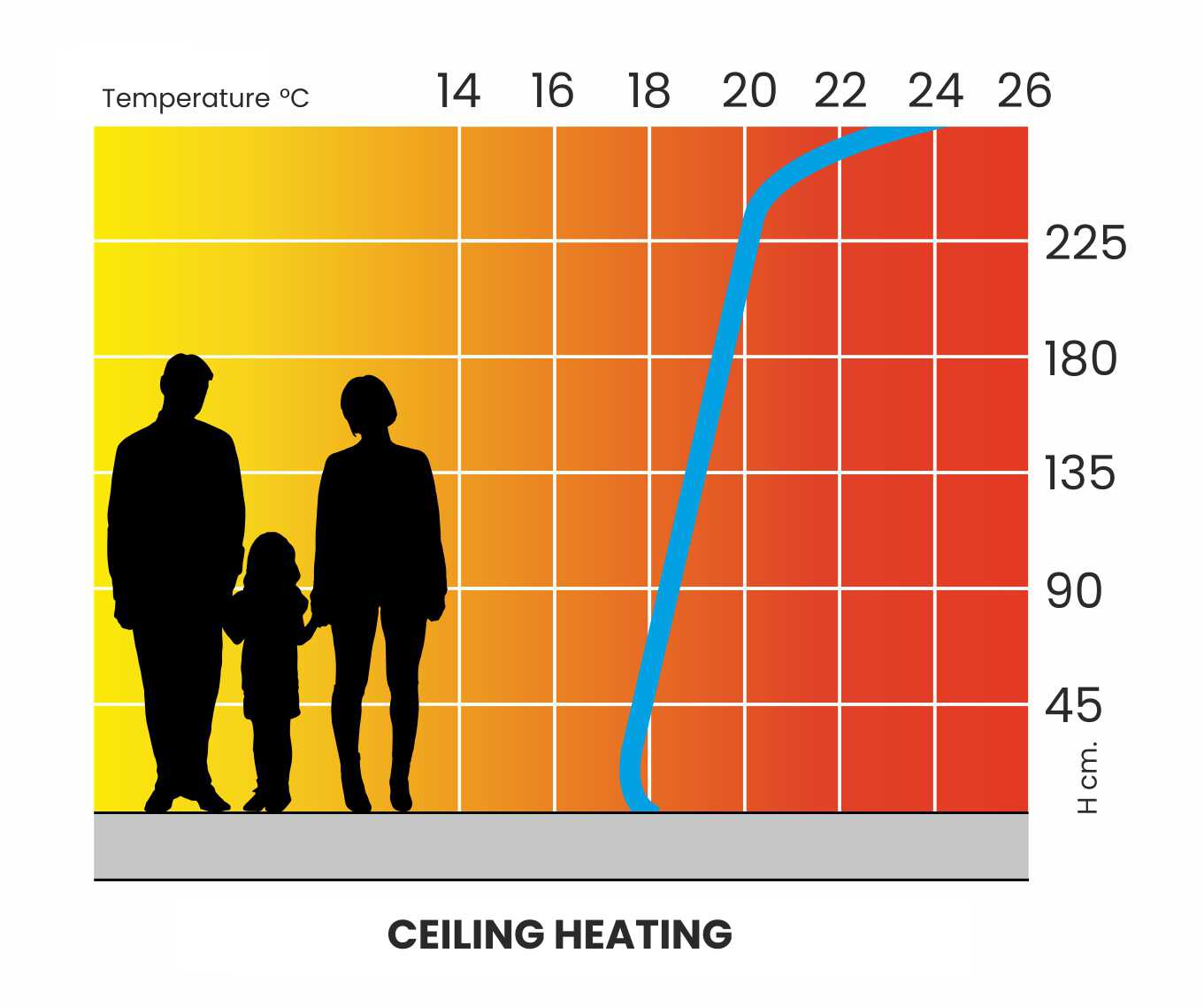

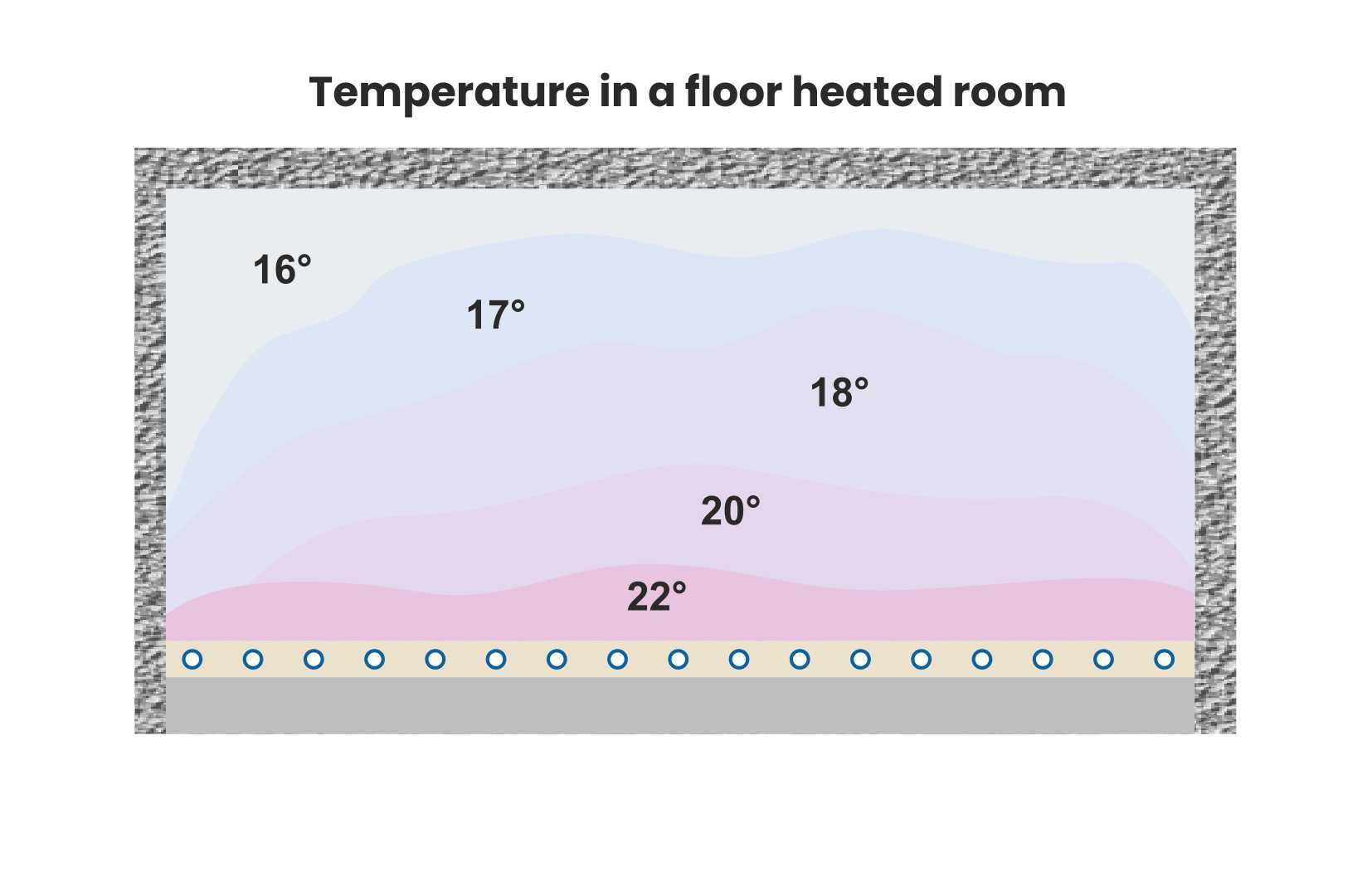

- Uneven distribution of heat or cool

- Limits in furnishing the rooms

- Difficulty of control and management

- Operating and maintenance costs

A system with radiators is based on the principle of heat transmission by convection and partly by radiation. Wall-mounted radiators emit “hot waves” to the surrounding environment, through their particular shape that favors the flow of air inside them. In order to heat the air in this way, a certain temperature difference is needed between the ambient air and that of the radiator. The water inside the radiators must have a temperature of at least 70 ° C, so that the radiator is able to adequately release heat to the air, which in turn must be set in motion to distribute itself in the rooms. The movement of air inevitably also leads to the movement of dust.

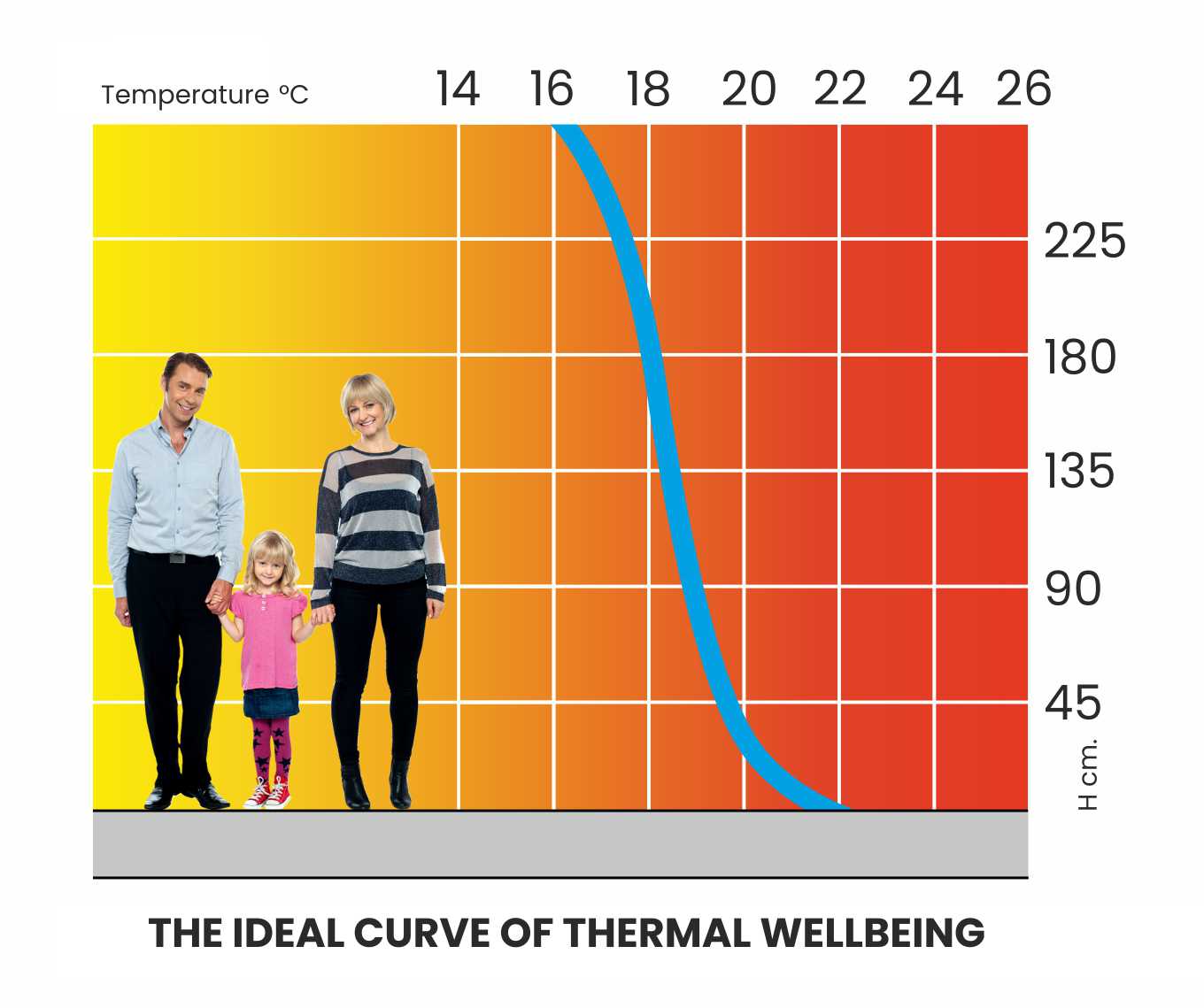

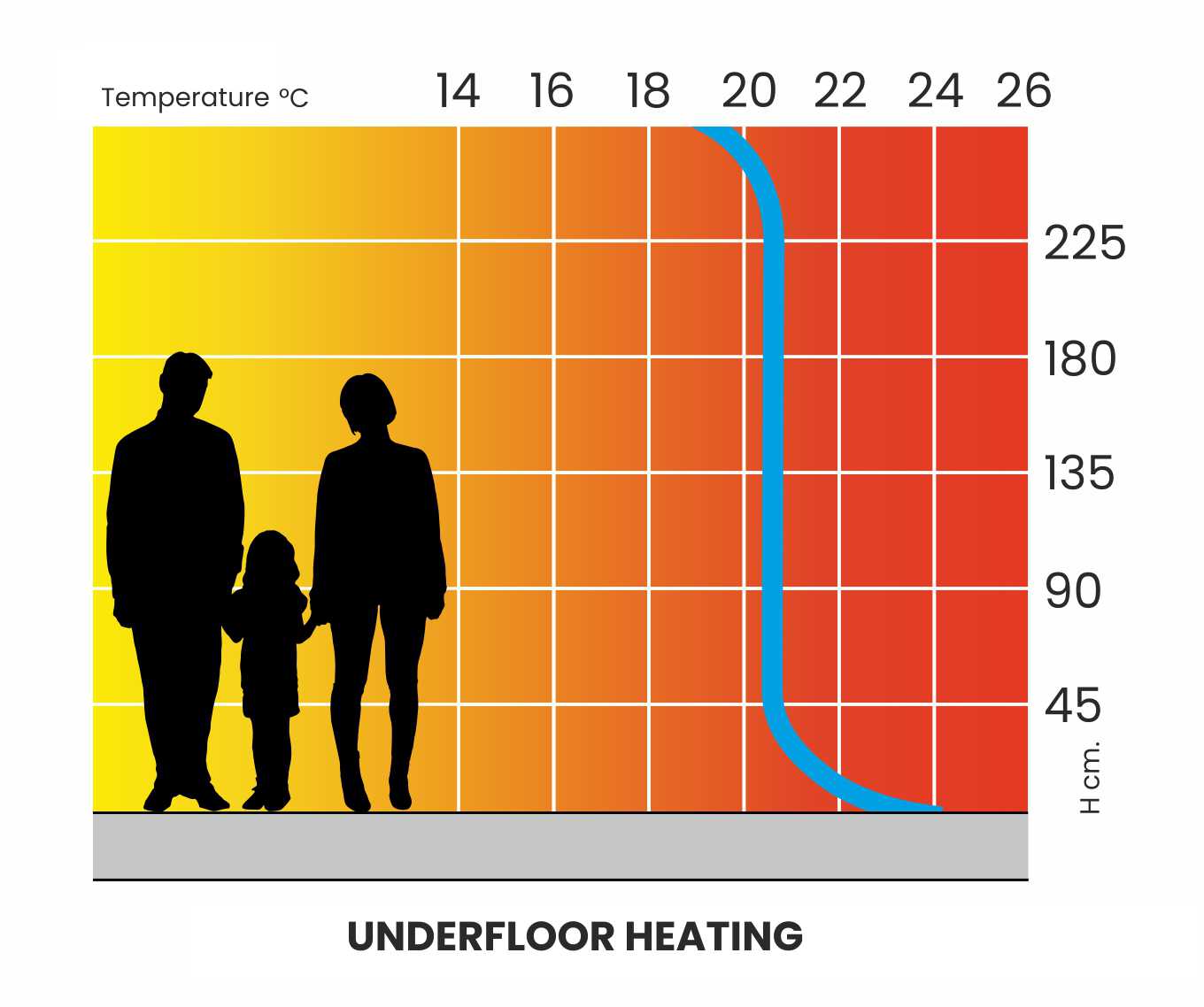

When, on the other hand, you live in a house with a heating system made with a radiant system, you get a completely different effect, that is, well-being without overheating the air! To understand this, just make a comparison. With respect to the perception of body heat, with a radiant system, the same comfort is obtained at a temperature of 17-18 ° C, equal to that achievable with a traditional system at 22 ° -23 ° C.

Before choosing a heating and cooling system it is necessary to know and study the characteristics of the building, both for a new building construction (more favorable situation) and for a renovation (sometimes more complex situation but advantageous from the tax incentives). It is of fundamental importance to study the heating system and the building structure, to avoid unpleasant surprises, both in the technical field and in the comfort expected by users.

Standards

Standards

In the vast panorama of technical standards and legislative provisions, radiant systems are divided into two categories:

- Embedded radiant systems (floor, wall and ceiling)

- Radiant systems with air gap (ceiling or wall)

A further and subsequent subdivision at the regulatory level concerns the application of radiant systems, or a subdivision between product standards and system standards. Product standards define the requirements and performance of radiant systems that manufacturers must follow. The system standards, on the other hand, are used by designers to carry out calculations and sizing; standards, therefore, which contain the requirements for the use of radiant systems in buildings.

The main product regulations are listed below:

UNI EN 1264 – Water-powered radiant systems for heating and cooling integrated into structures. The standard consists of 5 parts.

UNI EN 14037 – Radiant panels suspended from the ceiling for heating and cooling powered with water at a temperature below 120 ° C. The standard consists of 5 parts.

UNI EN 14240 – Ventilation of buildings – Cold ceilings – Tests and evaluation (rating).

The standard specifies the conditions and test methods to determine the cooling capacity of radiant ceilings in cooling.

The main system regulations are listed below:

UNI EN ISO 11855 – Design of the built environment – Design, sizing, installation and control of integrated radiant heating and cooling systems. The standard consists of 5 parts.

ISO 18566 – Building environment design – Design, test methods and control of hydronic radiant heating and cooling panel systems. The standard consists of 4 parts. The ISO 18566 standard concerns radiant ceiling panels consisting of an active part (elements with pipes in which water circulates) and a rear air gap..

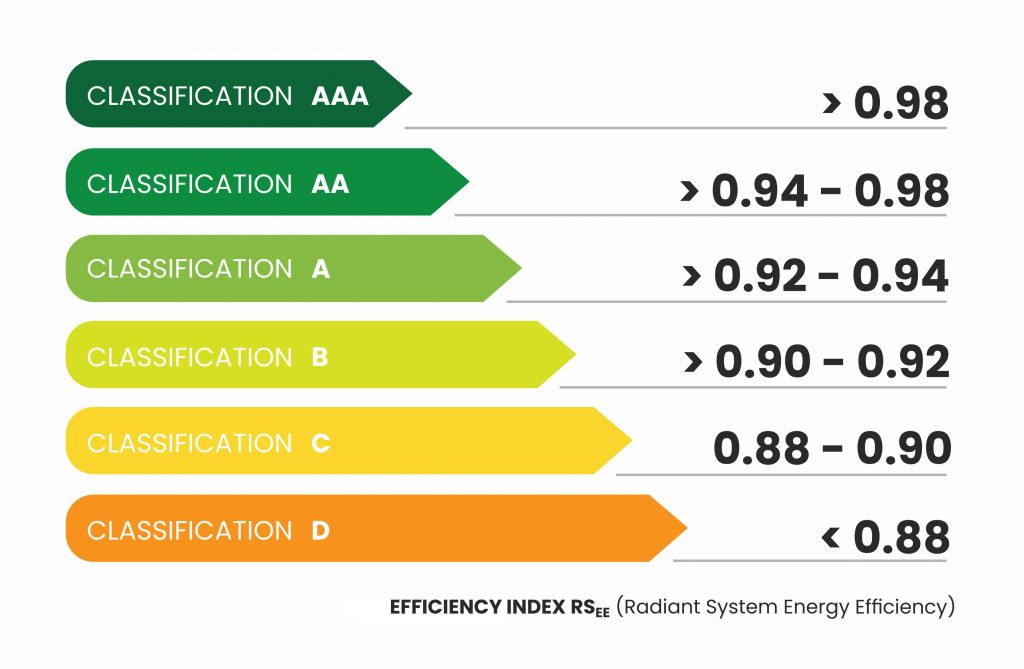

In 2016, the UNI / TR 11619: 2016 standard was published in Italy entitled “Low temperature radiant systems – Energy classification”. The standard describes the calculation of the efficiency index defined RSEE (Radiant System Energy Efficiency), which represents an overall indicator that involves the stratigraphy, the components of the radiant system, the regulation logics and the auxiliaries. The object of the classification are radiant systems with low temperature difference on the floor, ceiling and wall in winter heating.

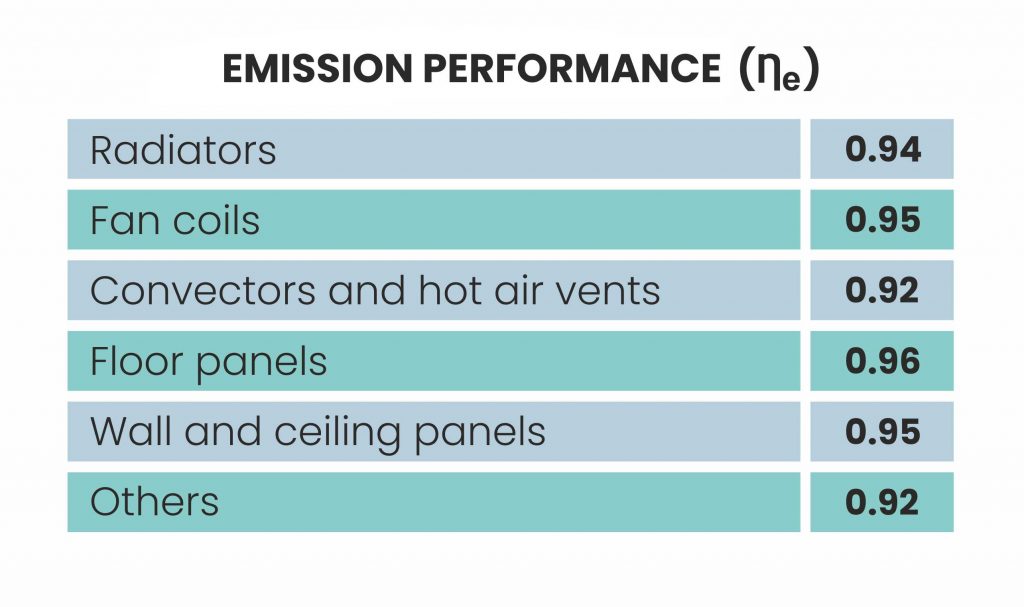

The determination of the global RSEE index involves the following process:

- Evaluation of emission efficiency

- Evaluation of the regulation efficiency

- Evaluation of the balance and efficiency of the circulators

- Calculation of the overall efficiency index of the RSEE system

The most used tool in Italy for calculating the energy performance of systems. This technical specification applies to newly designed, reconstructed or existing systems: for heating only, mixed or combined for heating and domestic hot water production, for only hot water production for sanitary use, for ventilation only systems, for ventilation systems combined with winter air conditioning, for lighting systems in non-residential buildings.

UNI/TS 11300-2:2014 -Energy performance of buildings – Part 2: Determination of primary energy requirements and yields for winter thermo-regulation, for the production of domestic hot water, for ventilation and for lighting in non-residential buildings residential. It specifies the data and calculation methods for determining the thermal energy needs useful for the domestic hot water production service, as well as the energy supplied and primary energy for winter thermo-regulation and domestic hot water services. The UNI / TS 11300 standard also provides the calculation method for determining the primary energy requirement for the ventilation service and the indications and national data for determining the primary energy requirements for the lighting service in accordance with UNI EN 15193. The technical specification provides data and methods for calculating the yields and losses of generation subsystems powered by liquid or gaseous fossil fuels.

Non-regulated professional activities – Installers of hydronic radiant systems with low temperature difference – Requirements for knowledge, skills and competence. The standard defines the knowledge, skill and competence requirements for installers of low temperature difference radiant systems (floor, wall and ceiling systems) combined with regulation strategies, dehumidification systems and controlled mechanical ventilation. These requirements are specified, starting from the specific tasks and activities identified, in terms of knowledge, skills and competence in accordance with the European Qualifications Framework (EQF) and are expressed in such a way as to facilitate the evaluation and validation processes of learning outcomes.

Rules

Rules

In the home, in the workplace, in public places, people like to stay while maintaining high standards of well-being. This feeling of pleasant satisfaction is only ensured by a uniform distribution of temperatures in the rooms, ensuring optimal comfort for any individual (adults, children, elderly) and in any external climatic condition. The most convincing and performing technical solution to reach the highest level of comfort is the radiant one. Through the exchange of energy between the surfaces (floors – walls – ceilings) and the rooms – mainly by radiation and minimally by convection – that pleasant condition of thermal well-being is obtained. All this, in the absence of convective air movements, without the need for heating elements and with a significant energy saving due to the use of lower operating temperatures than traditional systems.

In summary, here are the main advantages of radiant systems that can be installed on the floor, ceiling or wall.

- They ensure thermal comfort, temperature uniformity and the absence of air currents

- They have a low temperature difference emission

- They integrate with heat pumps and efficient boilers

- They are combined with VMC systems, ensuring high indoor air quality

- They have the widest range of adaptability

- They raise the commercial and qualitative value of the property

- They improve the energy class of the building

- They reduce consumption even without redeveloping the structure

- With a single system it is possible to heat and cool

- Eliminate mold and condensation problems in the home

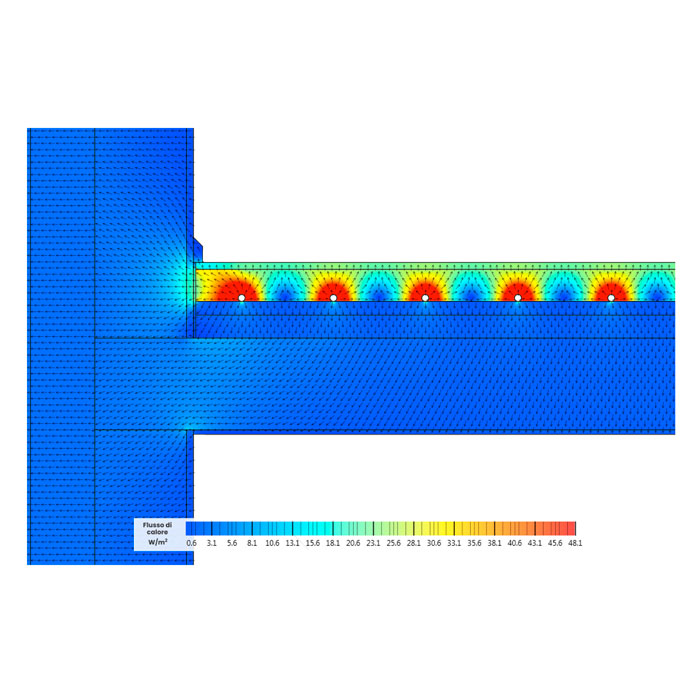

Irradiation – The heat exchange between the human body and the environment is regulated by four mechanisms: irradiation, evaporation, convection and conduction. Based on its own heat balance, our body perceives the greatest feeling of well-being when it can regulate at least 50% of its heat emission through radiation. The uniformity of irradiation and the constant temperature characteristic of the radiant floor systems, allow our body to experience the environment in the best conditions of thermal comfort.

The energy benefit – There is no doubt that awareness of energy saving has been considerably raised and the role of thermo-regulation of systems in buildings becomes decisive if the aim is to use alternative energy sources as much as possible. From this point of view, radiant systems are the essential solution. The low temperature of the fluid circulating in the circuits makes the radiant systems perfectly compatible with a whole series of energy sources: condensing boilers, heat pumps, thermal solar panels, as well as heat distribution systems such as district heating and waste recovery of industrial heat. This exceptional adaptability, in addition to being a benefit for the environment, translates into economic savings.

Thermal inertia – The use of insulating panels of different material, thickness, shape and characteristics, on which the “serpentine” pipes are laid, allows for a more performing thermal mass, favoring the installation of greater flexibility than to the trend of external climatic conditions, reducing the effects of thermal inertia..

![]() Solutions

Solutions

The choice of the most suitable radiant system starts from the diagnosis of the building object of the installation. By reason of the planned or existing thermal insulation, following the needs of living comfort expressed by users and being part of the overall project planned for the building, a radiant heating and cooling system offers multiple opportunities and solutions. First of all, the complete range of intended uses of the buildings: residential, office, commercial, offices and public facilities, sports facilities, buildings for worship, historic buildings. The extraordinary versatility of radiant systems lends itself as an excellent solution for both new buildings and redevelopments.

Taking into account the high levels of comfort and quality required by users today, the problem of summer cooling, which is now considered necessary, especially in the countries of the Mediterranean area, should not be underestimated. The low temperature difference radiant systems allow to operate, in the two phases of heating and cooling, with delivery temperatures close to those of the room to be regulated, determining a high quality of the internal environment together with high energy efficiency.

The solutions proposed by Bampi, in addition to being supported by internal skills, always take into account the data provided by the client and the expectations expressed in the design phase. Nothing is left to chance. What is going to materialize is a shared path in which considerations, advice and choices lead to produce a result on which the widest satisfaction must be gathered. The method adopted allows to focus on the objectives that inspire the project, giving extreme importance to the role of each participant (designer, builder, plumber, competent technician, end user).

The evolution and development of the raw materials used in the production of the various products that make the radiant system (pipes, manifolds, valves, etc.) and the related production technologies, inspire Bampi’s research path in the composition of a products package that allows to reach ever higher quality standards. All components in contact with the heat transfer fluid follow improvement processes aimed at obtaining oxygen permeability levels equal to zero, with the aim of eliminating – as far as possible – the phenomenon of corrosion induced by oxygen.

Sensitive and qualified for over twenty years to deal with the acoustic issue in the field of water drainage, Bampi addresses the design of the radiant system taking into account the needs in terms of acoustic impact. The design of the system, considering the structural partitions involved (whether floors, walls or ceilings), is carried out by involving the acoustic technician and – where it has not been foreseen – providing the widest advice on internal acoustic well-being. Dynamic stiffness of the insulating supports and fluid-dynamic sizing of the pipes are considered.

End user satisfaction is achieved through the conception of the most appropriate system control management: simplified or evolved, according to the needs of the house and adapting to the user’s expectations. The treatment of the air in the rooms with the aid of dehumidifiers with or without integration, suitably flanked by VMC with cross-flow water / gas / geothermal heat recovery units, within a design framework capable of integrating energy resources and requests of “comfort living”, constitute the guiding principles of every radiant project realized in Bampi.

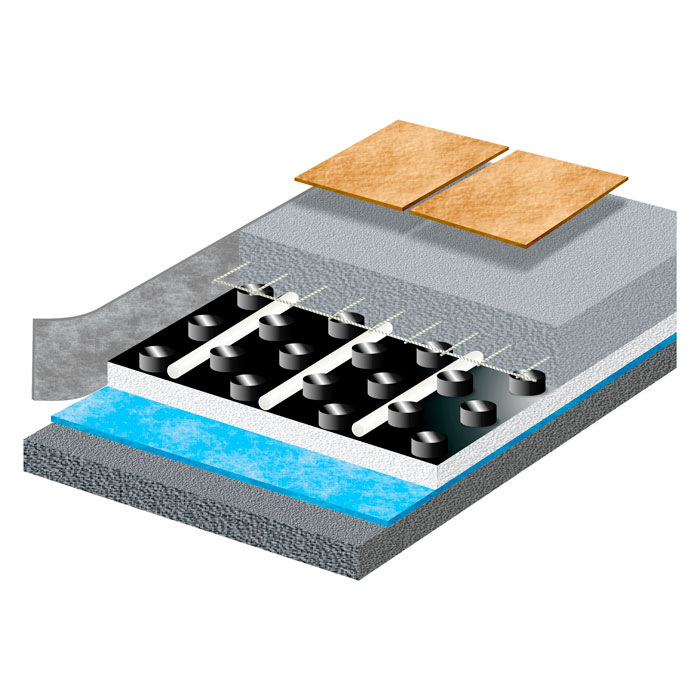

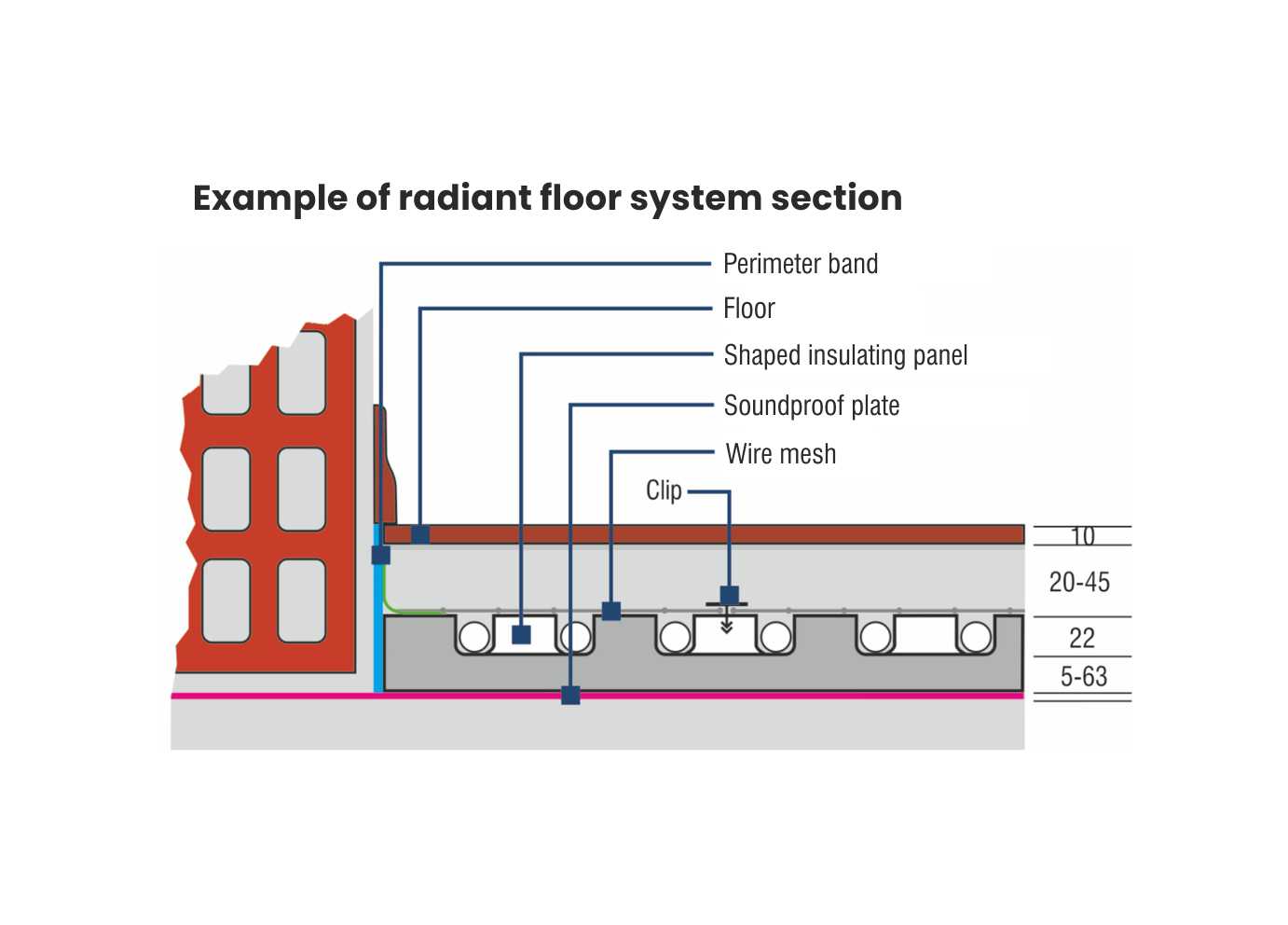

Considering the technical characteristics of the radiant systems and their exceptional versatility, they can be divided into 3 types: floor, ceiling and wall. They can have low and high thickness, or high and low inertia. Even in their installation and in relation to the site conditions, they can be made on site or dry.

- Radiant floor systems (radiation from bottom to top) divided into:

- SHAPED SYSTEMS

- FLAT SYSTEMS

- NET / BINARY SYSTEMS

- LOW THICKNESS SYSTEMS

- Vapor barrier and possible acoustic insulation layer

- Layers of thermal insulation

- Protective layer of the insulation layer

- Pipes available in PEXb/AL/PEXb – PEXc/EVOH/PEXc – PE/EVOH/PErt – PErt/EVOH/PEXa

- Static load distribution and heat diffusion layer (support layer – screed made on site or dry)

- Surface coating (with possible layer for its installation)

- Other components (perimeter strips, diffusers, etc.).

- Ceiling / wall radiant systems (radiation from top to bottom or from the wall to the room) divided into:

- WITH 16×2 multilayer PIPES

- WITH 10×1,3 multilayer PIPES

- Metal support frame

- Thermal insulation layers which can also have an acoustic function

- Pipes (available in PEXb/AL/PEXb or PEx) inserted in the support plates

- Pipe support layer (plasterboard sheets)

- Other components (connection pipes and fittings)

Problems

Problems Standards

Standards Rules

Rules Solutions

Solutions